Production and sales lease: aluminum template, disc scaffold, climbing frame

Search Results

There is a strong technical service team, and a training system has been established to enable on-site operators to operate skillfully in a short period of time, provide on-site technical support, and better cooperate with customers in construction.

Scaffolding is a temporary structure primarily used on construction sites to provide workers with a safe and stable work platform.

Work platform provided: Scaffolding provides a stable work platform for construction workers, enabling them to work at heights, such as bricklaying, painting, and installing doors and windows.

The support frame consists of vertical rods, horizontal rods, and diagonal rods. The disc has eight holes: four small holes for horizontal rods and four large holes for diagonal rods. Both horizontal and diagonal rods connect via a pin system, ensuring a secure connection to the vertical rods.

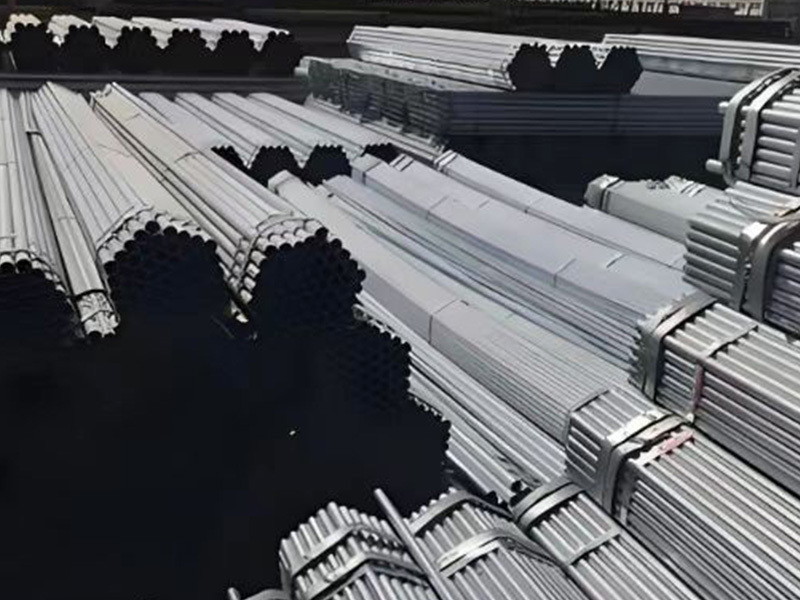

The main components of the hot-dip galvanizing process use an inner and outer hot-dip galvanizing anti-corrosion process, which not only improves the service life of the product but also provides further safety guarantees, while also achieving a beautiful and attractive appearance.

High frequency of reuse, low amortized cost: All components of the low-aluminum formwork system are reusable, and under standard construction conditions, they have a long service life; in the United States, there are records of aluminum formwork being used more than 300 times, resulting in a low amortized unit cost.

Lightweight and High Strength: Aluminum formwork for construction weighs approximately 30 kg/㎡, making it the lightest among existing metal construction formworks. The construction process can be completed entirely by manual assembly and transportation, without relying on hoisting machinery. (Workers typically only need a wrench and a small hammer, making it convenient and efficient). Experimental test data shows that the bending strength of aluminum alloy is three times that of ordinary steel, with tensile strength >180 MPa and yield strength >180 MPa.

Wide range of applications: Aluminum formwork can be used in a variety of building structures, such as super high-rise buildings, basements, residential buildings, and pipe galleries, with a load-bearing capacity of 50-60 kN/m².

Designed for one-time forming, rigorous construction, and high precision: The construction drawings are designed for one-time forming, with overall casting and rigorous construction. The major independent systems such as wall formwork, top formwork, and support are organically integrated. The formwork is fully assembled at one time to achieve one-time construction; with small errors and high precision, ensuring the overall strength and service life of the building. It is very suitable for high-rise standard floors, super-high-rise buildings, and multi-unit buildings of the same type.

Wide range of applications and strong load-bearing capacity: The aluminum formwork system is suitable for all building components, such as load-bearing walls, columns, beams, floor slabs, stairs, balconies, etc. It can be completed with a single pour of cement. The aluminum alloy building formwork system uses aluminum alloy plates for all parts. After assembly, the system forms an integral framework with excellent stability, strong uniformly distributed load-bearing capacity and concrete pressure-bearing capacity, effectively ensuring building quality.

High-quality construction results and omission of plastering: The construction results are excellent, with precise geometric dimensions. The verticality and flatness tolerances are controlled within 3-5mm, resulting in a smooth and flat surface that achieves or approaches the effect of a bare concrete wall. The joints are fine and the wall is beautiful, making later decoration convenient and reducing or eliminating the need for secondary plastering work, thereby lowering or eliminating plastering costs.

No construction waste is generated, and construction is safer; High recycling rate: Aluminum formwork does not rust, has no fire hazard, there are no nails on the construction site, no leftover wood chips and sawdust from electric saws, and other construction debris; the construction site is safe and clean. Aluminum formwork has high recycling value, and aluminum alloy materials can be continuously recycled, fully complying with the national low-carbon, environmentally friendly, green building, and sustainable industrial policies.

No construction waste is generated, and construction is safer; High recycling rate: Aluminum formwork does not rust, has no fire hazard, there are no nails on the construction site, no leftover wood chips and sawdust from electric saws, and other construction debris; the construction site is safe and clean. Aluminum formwork has high recycling value, and aluminum alloy materials can be continuously recycled, fully complying with the national low-carbon, environmentally friendly, green building, and sustainable industrial policies.

Reliable Quality This product, from raw material preparation to the final product, undergoes 20 to 30 processes. Each process utilizes specialized machinery to minimize human intervention, especially in the production of horizontal and vertical bars. We use self-developed, fully automated welding machines to achieve high product precision, strong interchangeability, and stable, reliable quality.

Taking the 60 series heavy-duty support frame as an example, the allowable load-bearing capacity of a single 5-meter-high upright is 9.5 tons (safety factor of 2). The ultimate load reaches 19 tons, which is 2-3 times that of traditional products.

Small amount, light weight. Generally, the spacing of the vertical poles is 1.5 meters and 1.8 meters, and the spacing of the horizontal poles is 1.5 meters. Larger spacing can reach 3 meters, and the spacing can reach 2 meters. Therefore, the amount used under the same support volume will be reduced by 1/2 compared with traditional products. The weight will be reduced by 1/2~1/3.

The disc-type connection method is the mainstream scaffolding connection method internationally. A reasonable node design ensures that the force of each member is transmitted through the center of the node. It is mainly used in European and American countries and regions, and is an upgraded product of scaffolding, with mature technology, firm connection, stable structure, and reliable safety.